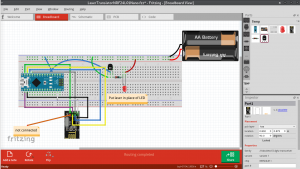

Test breadboards finished, populated and tested working (with LED’s) here.

First the RF controlled laser (nRF24L01+). couldn’t find any lasers in Fritzing parts 🙂

We plan on controlling more than 10 lasers, so made 4 of these on breadboard for the software test:

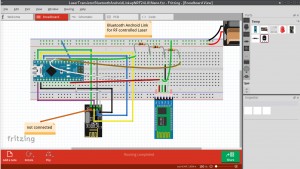

Next up is the Bluetooth Controller. This pairs via bluetooth to an Android app which then sends the correct on/off signal via RF to the Lasers.

Currently the signal is sent to all the lasers simultaneously, then they work who it was for according to what was sent. The signal is actually sending RGB codes, in case I want to add RGB in later, so should look like this: 1 255 0 0 means laser number 1 is on (or RGB led set to RED 255 full on).

1 0 0 0 would mean laser 1 off. The last 2 numbers are redundant but I am hoping to re-use the code for RGB LED’s at some point, so a couple of wasted bytes is nothing.

Speaking of wasted bytes, there is another byte for the node (the RF24 Arduino library uses the concept of nodes – up to 6 connected to each signaller)

I wanted to have more than 6 lasers and noticed if you define 2 nodes with the same address they both receive the signal. I am pretty sure that if 100 lasers are defined with the same node address they will still all receive the same signal. Then the software I have written can distinguish which laser is supposed to turn on, by parsing the 2nd argument. I am keeping the node byte for possible multi-setups.

Here is the full transmitted protocol:

Node

Laser

Red

Green

Blue

– using RED value for on/off on the one laser I have connected on the receiver side.

-soon we will have multi-lasers!